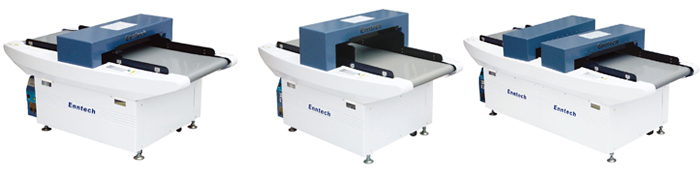

NEEDLE DETECTOR

Needle Detector has a self-driving, environment friendly and electricity saving design. The counter on the manipulator can effectively calculate certified and uncertified products and their gross. The lighting indicator for sensitivity and inductance indicates the anti jamming intensity and check up capacity of the machine directly. The indication for corresponding check-up location on the manipulator makes it convenient for the operator to find the exact location of the broken needle, which is effective for the normal model and the NC model. Under the normal model circumstance, the machine can protect automatically the over length of the product being checked for the broken needle, whose radius is over 1.00mm. At this point, the machine makes a sound and the conveyer is halted, then the transporting belt unthreads and lays back the product.

Model |

HD-650 CE-10 |

HD-650 CE-15 |

HD-650 CE-20 |

HD-1200 CE-15 |

Detecting method Detecting Ability Detecting adjustment Detecting width Detecting height Alarm Method Belt Speed Power Supply Rated Out Put Printer Dimension LxWxH Weight |

Magnetic induction 0.8-1.00mm(Dia) Fe Part Stepless adjustment 600mm 100mm Buzzer&belt stops 30m/min 250v.50Hz,single phase 110w Option 1650(L)x1050(W)x900(H)mm 200kg Approx |

Magnetic induction 1.2mm(Dia) Fe Part Stepless adjustment 600mm 150mm Buzzer&belt stops 30m/min 250v.50Hz,single phase 110w Option 1650(L)x1050(W)x930(H)mm 230kg Approx |

Magnetic induction 1.5mm(Dia) Fe Part Stepless adjustment 600mm 200mm Buzzer&belt stops 30m/min 250v.50Hz,single phase 110w Option 1650(L)x1050(W)x960(H)mm 250kg Approx |

Magnetic induction 1.2mm(Dia) Fe Part Stepless adjustment 1200mm 150mm Buzzer&belt stops 30m/min 250v.50Hz,single phase 110w Option 1650(L)x1650(W)x1050(H)mm 360kg Approx |